Parts and Tools

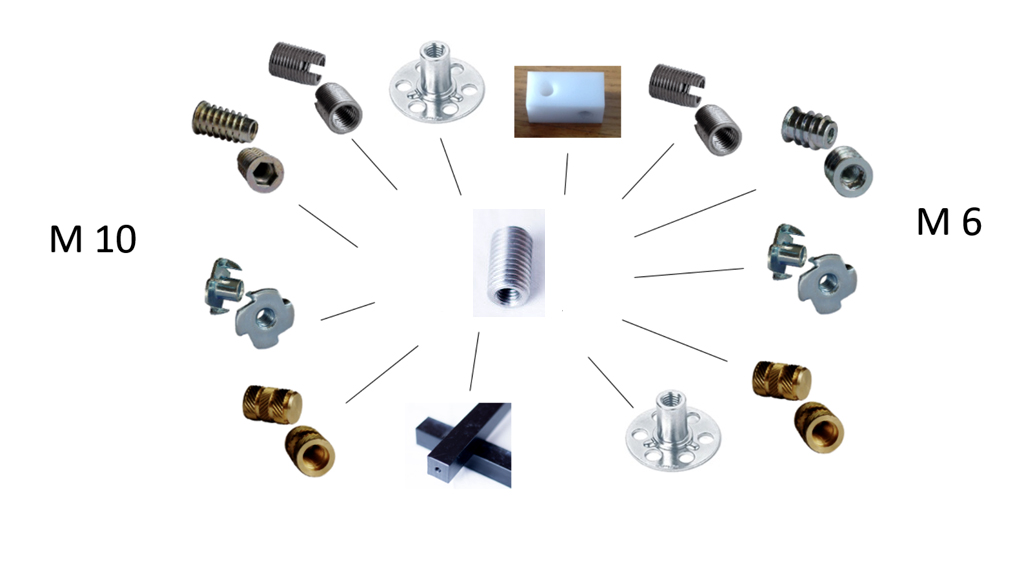

– The differential thread connector

– Threaded fixing points (inserts or tapped holes)

– Treaded stud (pin) with hex socket

– Hex tools (Allen keys)

Only the connector is custom made

How it Works

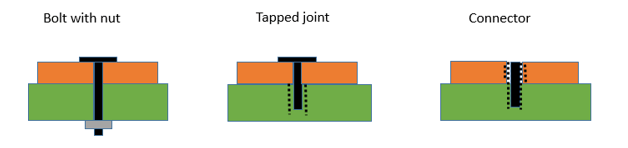

The essential part is the differential thread connector that connects objects with threaded fixing points of different pitch, (M6 and M10 in prototypes shown). The connector is a metal cylinder with external threads (M10) and internal threads (M6) and a hex socket. The connector is placed inside the M10 fixing point in the first object, a threaded pin (M6) is threaded through the connector and into the M6 fixing point in the second object. The desired clamping effect is obtained by turning the connector counter-clockwise.

Features

- An alternative to bolted joints and traditionally partly tapped joints

- Enhanced strength and stiffness of joint due to improved load distribution, reduced grip length and elimination of bolt-hole clearance

- Strong clamping force, friction only in threads, predictable torque/tension ratio

- Applicable to objects of wood, plastics, metal, composites, with threaded inserts or tapped fixing points

- Low profile, cosmetic appearance, blind access to second object

- Non-destructive disassembly